What is Softgel Encapsulation?

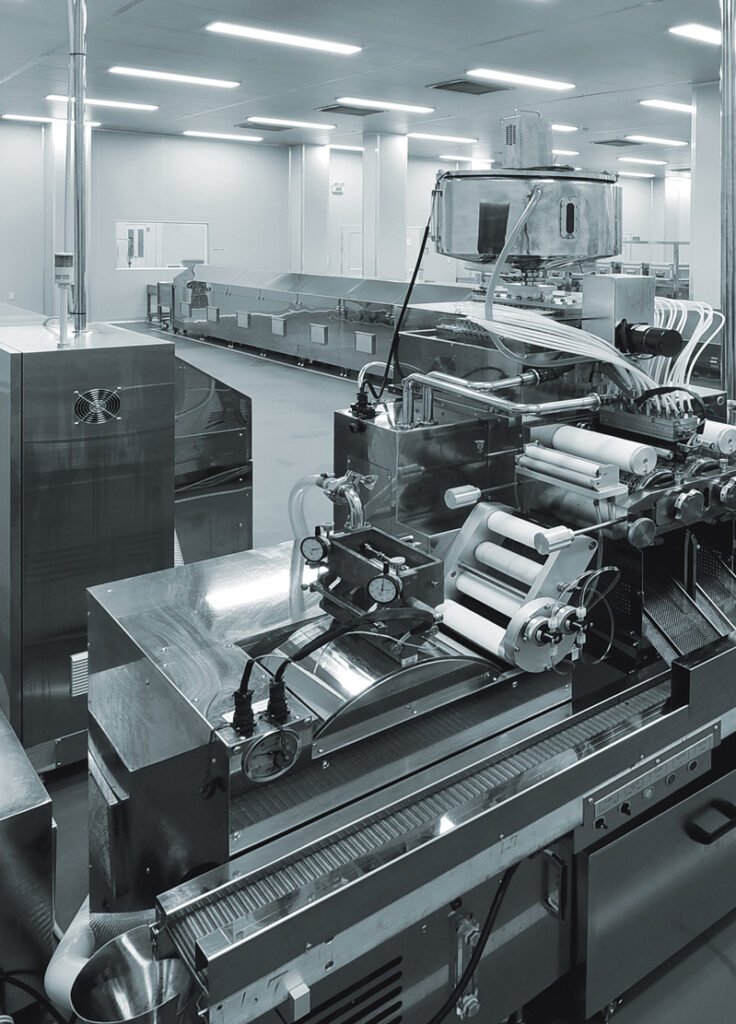

Softgel capsules are a type of oral dosage form that consist of a soft, gel-like material that encapsulates a liquid or semi-solid medication. The encapsulation process involves filling a gelatin-based shell with a liquid or semi-solid medication and then sealing the shell to form a softgel capsule. Softgel encapsulation machines play a crucial role in this process by automating and streamlining the production of softgels. We offer a range of products, including machines for high-speed production, machines for small-scale production, and machines that can be customized to meet specific production needs. We also are involved in maintenance and repair services to ensure that their machines remain in top condition.

Steps of Softgel Manufacturing:

Formulation Development

The first step in the softgel manufacturing process is the development of the formulation, which involves creating a recipe for the softgel that contains the active ingredient and any excipients or fillers. The formulation must be designed to meet specific requirements, such as stability, bioavailability, and appearance.

Gelatin Melting

Once the formulation is complete, the gelatin must be melted in order to create the shells for the softgels. This typically involves heating the gelatin to a temperature of around 80°C until it is fully melted.

Filling

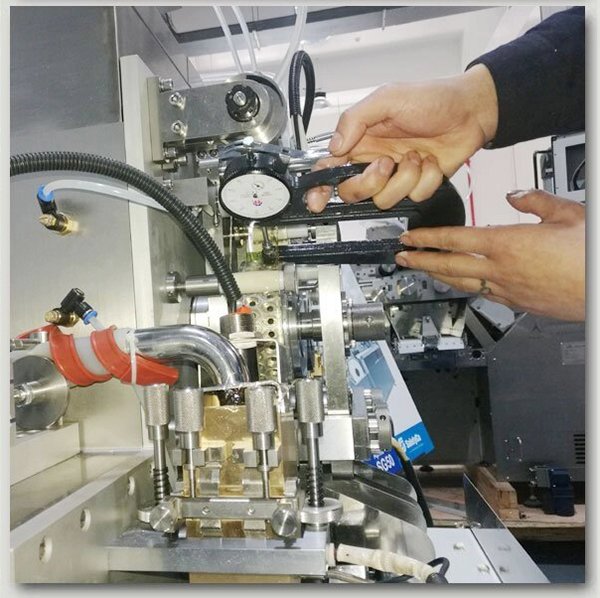

The next step is filling the melted gelatin into the encapsulation machine's molding plates. The filling process involves adding the liquid or semi-solid medication to the melted gelatin and then sealing the mold to form the softgel shells.

Drying and Hardening

After the softgel shells have been formed, they must be dried and hardened. This typically involves placing the shells in a cooling unit that reduces the temperature and allows the gelatin to set.

Final Packaging

Once the softgels have been dried and hardened, they are ready for final packaging. This typically involves counting and inspecting the softgels, and then packaging them in a manner that protects them from damage and ensures their stability.

Filling

The next step is filling the melted gelatin into the encapsulation machine's molding plates. The filling process involves adding the liquid or semi-solid medication to the melted gelatin and then sealing the mold to form the softgel shells.

Neurology care

Sollicitudin aliquam ultrices sagittis orci a scelerisque purus semper eget. Convallis morbi leo urna.

heart specialist

Gravida in fermentum et sollicitudin. Lorem mollis aliquam ut porttitor leo a diam enim sit amet venenatis urna.

pulmonology care

Amet massa vitae tortor condimentum lacinia quis. Arcu ac tortor dignissim convallis purus gravida aenean.